Oxygen Gas Plant

The SANGHI-ORG Oxygen Gas Plant, is safe and economical to operate. It comes with an efficient expansion engine. which lowers the operating pressures remarkably to as low as 32-35 kg/cm2 and also cuts down power consumption.

A Molecular sieve Battery drier unit for separation of moisture and carbon dioxide is another money-saving device in the SANGHI-ORG plant. It removes acetylene and other hydro-carbons from the process air. eliminating the need for separate acetylene absorbers, and moreover it eliminates recurring caustic soda costs.

The SANGHI-ORG Oxygen Gas Plant is capable of simultaneously producing high purity Oxygen Gas and Nitrogen Gas. It also has an internal compression Liquid Oxygen Pump to fill dry gaseous oxygen in cylinders.

We also undertake supervision of Installation and Commissioning of the SANGHI-ORG Oxygen Plant.

We are highlighting some of the salient features of Sanghi-Org Oxygen Gas Plants :

1. Sanghi-Org Standard capacity Oxygen Gas Plants are power efficient and consumes only 1.0 to 1.2 Kw unit of electricity for every cubic meter of Oxygen gas produced. under normal operating & running condition and continuous operation of the Plant.

2. Sanghi-Org Oxygen Gas Plants take only 8 hours to come in production after defrosting and the defrosting cycle would be once in about 10 to 12 months only.

3. Sanghi-Org Oxygen Gas Plant will also be in a position to simultaneously produce Gaseous Nitrogen at a purity of about 99.999% by L. N. Pump.

4. The design features and high quality inputs of raw materials of Sanghi-Org Oxygen Gas Plants help in achieving optimum production, generally higher than the rated capacity.

5. Sanghi-Org Oxygen Gas Plants provides easy access for maintenance, as explained at length in user friendly, exhaustive operation manual.

6. Sanghi-Org Oxygen Gas Plants are supplied with a Liquid Oxygen Pump which is simple. It operates to fill bone dry gas into cylinders at the requisite pressure Depending on the liquid level in the Condenser. our pump operates and handles the quantity available without any changes in its speed.

7. Sanghi-Org Oxygen Gas Plant is supplied with super-efficient Expansion Engine with our Plants. This helps in rapidly developing initially to reduce the start-up time and also in maintaining required low temperature during the entire plant operation. which not only ensures optimum production but also helps in conserving power. Further our Plants are of medium pressure.

8. Sanghi-Org Oxygen Gas Plants along with cylinder filling stations can be housed in a compact area

ASU & Expansion Engine of 600 cum/hr Oxygen Plant

M.S. Battery for 600 cum/hr Oxygen Plant

Plant Specifications

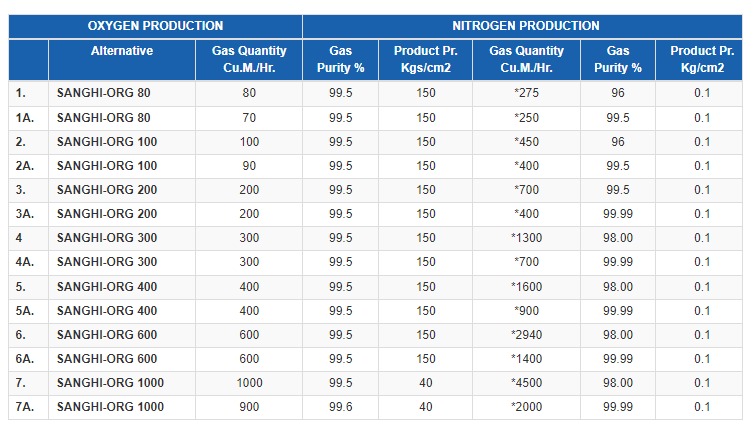

1. Production Capacity – The plant is very versatile and can be set for a cycle to produce any one of the following alternatives:-

The above product capacities are based on ambient conditions of 15oC temperature 760mm of Hg pressure and 50% relative humidity and 0.03% of Carbon Di-oxide is allowed as impurity.

Note:

1) High purity Nitrogen of upto 2 PPM can also be tapped simultaneously with a separate liquid Nitrogen pump in modified plants , at an additional cost.

2) Provisions can also be made for tapping upto 25% liquid oxygen / liquid nitrogen simultaneously with gaseous oxygen, at an additional cost.

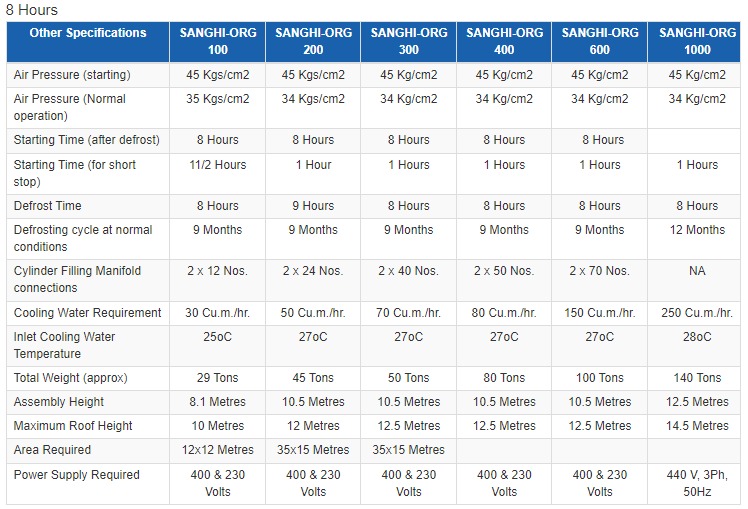

2. Other Specifications:

Note:

1) Electric motors can be supplied to suit specific power ratings in respective countries across the globe, if informed in advance.

Note:

1) High purity Nitrogen of upto 2 PPM can also be tapped simultaneously with a separate liquid Nitrogen pump in modified plants , at an additional cost.

2) Specifications of other capacity plants upto 750 Cu.m/hr capacity can be furnished on request. 2) Provisions can also be made for tapping upto 25% liquid oxygen / liquid nitrogen simultaneously with gaseous oxygen, at an additional cost.

Description of SANGHI-ORG Oxygen Plant

The free atmospheric air is sucked in by a multi-stage air compressor through a filter and compressed to the working pressure. After each stage, intermediate coolers and water separators are provided. The compressed air then passes through the (evaporation) pre-cooler and then to the molecular sieve battery where the moisture and carbon dioxide are removed from the process air. It then passes through the exchanger No. 1 where it is cooled by the out-going waste nitrogen and product oxygen.

A part of this cold air then flows through an expansion machine and the balance through the 2nd heat exchanger. The ratio of the two air streams is controlled by an expansion valve, RI.

Both these streams of air then unite in the lower pressure column where it partially liquefies.

The liquid air (rich air) then passes through the expansion valve R2 to the upper column which is at a lower pressure than the lower column. Similarly the liquid nitrogen (poor liquid) travels from the lower column to the upper column through an expansion valve R3 where the separation of oxygen and nitrogen occurs. Nitrogen being more volatile passes out as a gas from the top of the column and this waste nitrogen flows through both the heat exchangers cooling the in-coming air. Similarly product oxygen is also passed through the two heat exchangers to cool the in-coming air and then to the filling manifold via a liquid pump. If a small amount of air is vented out from the upper column, higher purity nitrogen can also be obtained from this plant. R4 Valve is provided in order to fasten cooling during start-up.

Oxygen Plants, Oxygen Gas Plant Manufacturer | Sanghi Organization.

Benefits of Oxygen Gas plants :

Oxygen Gas plants Ensures a steady supply of oxygen

Oxygen Gas plants Cost-effective in the long run

Oxygen Gas plants installed in-house provides independence from external sources of Liquid Oxygen & Gaseous Oxygen supply

Oxygen Gas Plants can be customised to suit specific requirements of Capacity.

Cryogenic oxygen Gas plants utilise low-temperature distillation technique to create oxygen gas required for Industrial & Medical applications.

Cryogenic Oxygen Gas Plants produce good Purity og Oxygen at 99.6 % purity.

Cryogenic Oxygen Gas Plants are Power efficient.